Your Vapor barrier thickness for walls images are ready in this website. Vapor barrier thickness for walls are a topic that is being searched for and liked by netizens today. You can Find and Download the Vapor barrier thickness for walls files here. Find and Download all free photos and vectors.

If you’re looking for vapor barrier thickness for walls images information connected with to the vapor barrier thickness for walls keyword, you have pay a visit to the right site. Our website always provides you with hints for downloading the highest quality video and picture content, please kindly hunt and locate more informative video content and graphics that fit your interests.

Vapor Barrier Thickness For Walls. OK people for the 957th time. That vapor barrier is laid directly on the dirt and the seams are overlapped at least 12 inches. We recommend using a vapor barrier of 16 mil or higher. While there are different kinds of vapor barriers the most common is poly and it comes in different thicknesses.

Polyethylene Moisture Barrier 30 X 100 Roll 30 Mil Thickness Foundation Waterproofing Membrane Barrier Membrane From pinterest.com

Polyethylene Moisture Barrier 30 X 100 Roll 30 Mil Thickness Foundation Waterproofing Membrane Barrier Membrane From pinterest.com

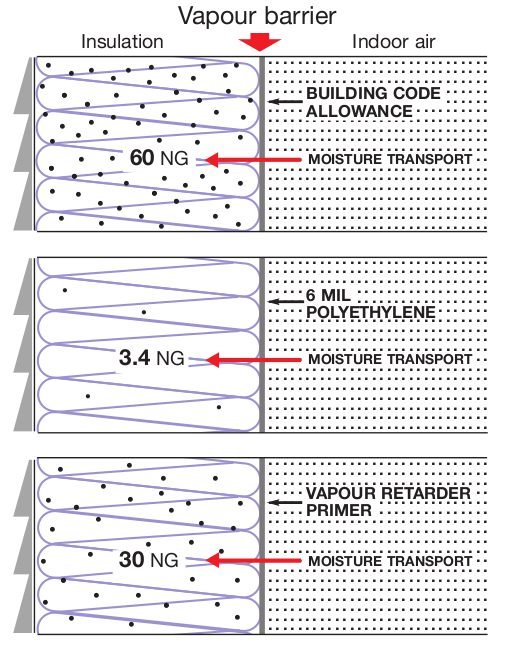

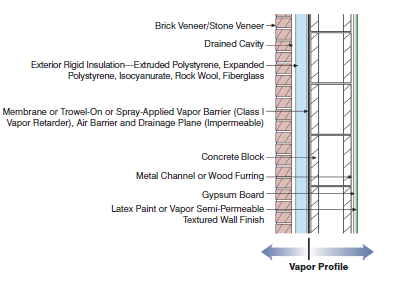

In some cases both a 6 mil and 4 mil. Vapor barriers should be at least 6 mil in thickness to effectively cover the area and create a moisture barrier. However they often prevent assemblies from drying. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. Building codes usually require a vapor barrier 4 mil plastic sheeting on exterior basement walls if the framing is attached to masonry or concrete surfaces or if the wood framing butts up against the outer basement walls. This translates into a permeance rate of only 0015 This is considered impermeable in American building codes.

For some products permeance increases with increasing relative humidity.

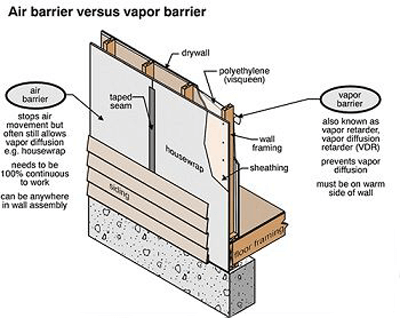

You can make a vapor barrier out of any unbroken surface thats impermeable to water vapor. Choosing a Crawlspace Vapor Barrier Thickness Mils. The other vapor barrier is created with your floor. Building codes usually require a vapor barrier 4 mil plastic sheeting on exterior basement walls if the framing is attached to masonry or concrete surfaces or if the wood framing butts up against the outer basement walls. This can be a problem when there is also a vapor barrier. Considered vapor permeable not a vapor retarder.

Source: pinterest.com

Source: pinterest.com

Choosing a Crawlspace Vapor Barrier Thickness Mils. Polyethylene plastic is a good material to use in a thickness between 0002 and 0008 inches 005 to 02 millimeters. However they often prevent assemblies from drying. Permeance typically decreases with increasing thickness. In most states a 6 mil vapor barrier is required.

Source: pinterest.com

Source: pinterest.com

Triangle Crawl Space Solutions uses both a 6 mil material for simple vapor barrier installation and a thicker more durable 12 mil vapor barrier material depending on the budget and needs of. This translates into a permeance rate of only 0015 This is considered impermeable in American building codes. Standard Installation Practices Six-mil polyethylene plastic comes in rolls. Polyethylene plastic is a good material to use in a thickness between 0002 and 0008 inches 005 to 02 millimeters. Incorrect use of vapor barriers is leading to an increase in moisture related problems.

Source: pinterest.com

Source: pinterest.com

No VB is perfect. 15-Mil Barrier A 15-mil barrier is slightly thicker and better than 6-mil 10-mil and 12-mil vapor barrier liners. You should then use fiberglass insulation that has a vapor barrier between the studs with the vapor barrier facing in toward the living space. Remember that these are minimums the greater the R-value of the foam the better as this creates a warmer wall cavity with less condensation. If you have more than one barrier in the thickness of the wall you will trap moisture in the middle.

Source: de.pinterest.com

Source: de.pinterest.com

3 Use an effective interior air barrier to keep warm moist interior air out of the wall cavities. How did this project turn out. Based on testing over different kinds of base materials the ACI determined that a polyethylene vapor retarder should be at least 10 mils thick although the 20 mil sheet performed better than any of the sheets and had no perforations at all. Remember that these are minimums the greater the R-value of the foam the better as this creates a warmer wall cavity with less condensation. Incorrect use of vapor barriers is leading to an increase in moisture related problems.

Source: pinterest.com

Source: pinterest.com

However they often prevent assemblies from drying. ONLY ONE VAPOR BARRIER MAXIMUM IN THE WALL. This can be a problem in any below grade space. Based on testing over different kinds of base materials the ACI determined that a polyethylene vapor retarder should be at least 10 mils thick although the 20 mil sheet performed better than any of the sheets and had no perforations at all. However there are some states where you can use a 4 mil vapor barrier if you want to.

Source: pinterest.com

Source: pinterest.com

Wall components have vapor retarding characteristics that can affect moisture migration. Triangle Crawl Space Solutions uses both a 6 mil material for simple vapor barrier installation and a thicker more durable 12 mil vapor barrier material depending on the budget and needs of. Based on testing over different kinds of base materials the ACI determined that a polyethylene vapor retarder should be at least 10 mils thick although the 20 mil sheet performed better than any of the sheets and had no perforations at all. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. No VB is perfect.

Source: pinterest.com

Source: pinterest.com

This can be a problem in any below grade space. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. Remember that these are minimums the greater the R-value of the foam the better as this creates a warmer wall cavity with less condensation. This can be a problem in any below grade space. The thickness of the vapor retarder should be determined by the necessary permeability and how sharp the compacted base will be.

Source: ecohome.net

Source: ecohome.net

Wall components have vapor retarding characteristics that can affect moisture migration. This can be a problem when there is also a vapor barrier. If you install the vapor barrier on the cold side of the insulation ie the inside of the brick you will trap moisture inside the walls and make the moisture problems worse. The perm rating represents how readily water vapor will pass through a material. Its not rocket science.

Source: pinterest.com

Source: pinterest.com

If you install the vapor barrier on the cold side of the insulation ie the inside of the brick you will trap moisture inside the walls and make the moisture problems worse. The perm rating represents how readily water vapor will pass through a material. A continuous plastic vapor barrier behind the drywall will protect the interior walls of these areas from water damage. Standard Installation Practices Six-mil polyethylene plastic comes in rolls. You should then use fiberglass insulation that has a vapor barrier between the studs with the vapor barrier facing in toward the living space.

Source: eco-home-essentials.co.uk

Source: eco-home-essentials.co.uk

OK people for the 957th time. Standard Installation Practices Six-mil polyethylene plastic comes in rolls. Its not rocket science. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. This can be a problem when there is also a vapor barrier.

Source: echotape.com

Source: echotape.com

The other thing you should look for when choosing a vapor barrier product is how that barrier is constructed. If you have more than one barrier in the thickness of the wall you will trap moisture in the middle. Permeance typically decreases with increasing thickness. Polyethylene sheeting is measured in mils A mil is equal to 0001 inch of thickness. This will give you two vapor barriers.

Source: pinterest.com

Source: pinterest.com

In most states a 6 mil vapor barrier is required. Vapor barriers installed on the interior of assemblies prevent assemblies from drying inward. The other vapor barrier is created with your floor. That vapor barrier is laid directly on the dirt and the seams are overlapped at least 12 inches. This translates into a permeance rate of only 0015 This is considered impermeable in American building codes.

Source: pinterest.com

Source: pinterest.com

The thickness of the vapor retarder should be determined by the necessary permeability and how sharp the compacted base will be. Permeance typically decreases with increasing thickness. This translates into a permeance rate of only 0015 This is considered impermeable in American building codes. Remember that these are minimums the greater the R-value of the foam the better as this creates a warmer wall cavity with less condensation. These numbers assume that the wall.

Source: fi.pinterest.com

Source: fi.pinterest.com

This translates into a permeance rate of only 0015 This is considered impermeable in American building codes. You should then use fiberglass insulation that has a vapor barrier between the studs with the vapor barrier facing in toward the living space. This can be a problem when there is also a vapor barrier. The perm rating represents how readily water vapor will pass through a material. You can make a vapor barrier out of any unbroken surface thats impermeable to water vapor.

Source: pinterest.com

Source: pinterest.com

Wall components have vapor retarding characteristics that can affect moisture migration. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. However there are some states where you can use a 4 mil vapor barrier if you want to. The other thing you should look for when choosing a vapor barrier product is how that barrier is constructed. The thickness of the vapor retarder should be determined by the necessary permeability and how sharp the compacted base will be.

Source: nl.pinterest.com

Source: nl.pinterest.com

Standard Installation Practices Six-mil polyethylene plastic comes in rolls. You should then use fiberglass insulation that has a vapor barrier between the studs with the vapor barrier facing in toward the living space. For Zone 5 the IRC and IECC recommend minimum R-5 foam sheathing for 24 walls and R-75 for 26 walls. How did this project turn out. Considered vapor permeable not a vapor retarder.

Source: energy-models.com

Source: energy-models.com

Triangle Crawl Space Solutions uses both a 6 mil material for simple vapor barrier installation and a thicker more durable 12 mil vapor barrier material depending on the budget and needs of. Standard Installation Practices Six-mil polyethylene plastic comes in rolls. While there are different kinds of vapor barriers the most common is poly and it comes in different thicknesses. The lower the perm rating the. Polyethylene sheeting is measured in mils A mil is equal to 0001 inch of thickness.

Source: pinterest.com

Source: pinterest.com

Ever look at a double-pane window that no longer. Vapor barriers were originally intended to prevent assemblies from getting wet. These flimsy liners are also very difficult to attach to walls and can be easily pulled down and they may not completely prevent moisture and vapor intrusion. This will give you two vapor barriers. Vapor barriers should be at least 6 mil in thickness to effectively cover the area and create a moisture barrier.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title vapor barrier thickness for walls by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.